Square One Armoring Services

Protecting Lives

Around the World

Square One strives to offer the highest levels of armor protection available and the best customer service and value in the industry. All of our products and services receive the full support of our sales, engineering, and production staff.

The Science of Protection

This allows for the most thorough evaluation of ballistic coverage and structural integrity prior to initial prototyping.

Practical Analysis

Material Assurance

Square One Armoring Services has very strict guidelines in place. All opaque and transparent armor materials have independent ballistic certifications, including Beschussamt Ulm and Mil-Spec documentation.

As an additional level of quality control, Square One periodically tests batch samples from the opaque and transparent armor inventory.

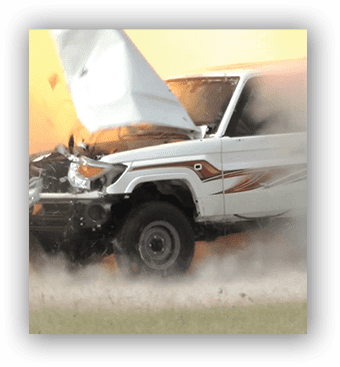

Complete System Validation

Square One Armoring Services is one of the few armoring companies in the world that goes through an extensive and rigorous testing process for its complete armor system

designs.

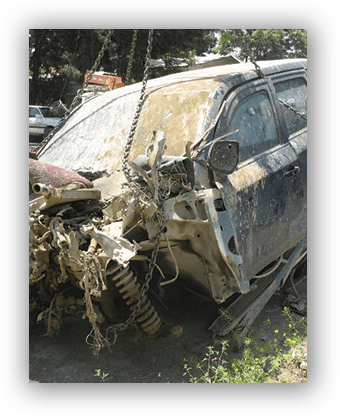

Real World Survivability

The culmination of all of the strict design, testing, and quality standards has resulted in armor systems that have been demonstrated to provide real-world survivability.