Services

The Science of Protection

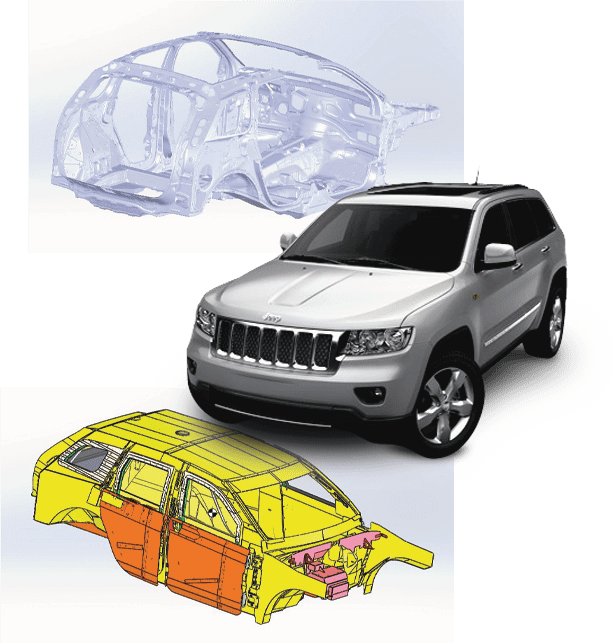

In addition to having one of the strongest engineering departments in the industry, Square One Armoring Services has one of the most experienced Research and Development departments with over 30 years of experience in opaque and transparent armor materials and the appropriate integration methodology for each type.

Practical Analysis

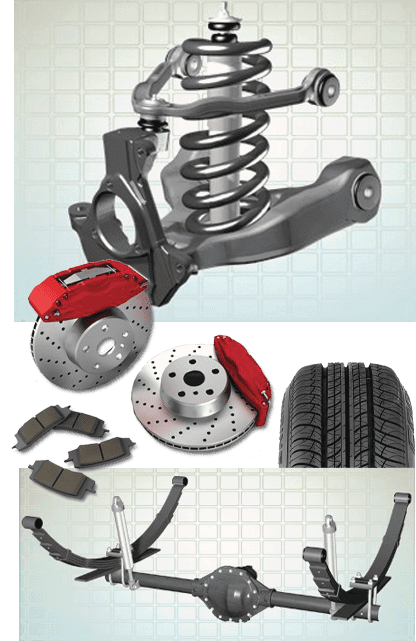

In addition to the many standard system upgrades, such as running flat inserts and self-sealing fuel tanks, our engineering department carefully selects the proper suspension, brake, and tire upgrades that are necessary to provide peak performance, vehicle stability, and durability.

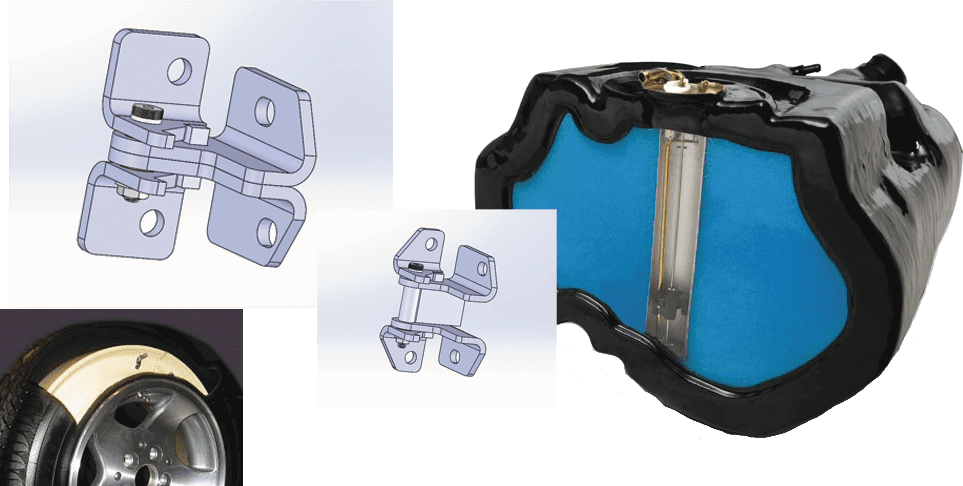

Many simple yet critical upgrades, such as door hinges, are typically overlooked. Square One Armoring designs and fabricates all new hinges for proper additional weight distribution.

Material Assurance

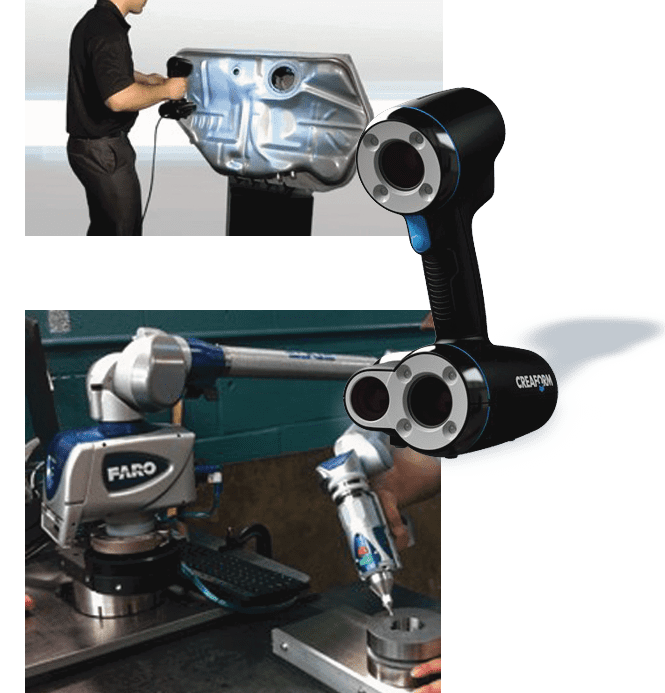

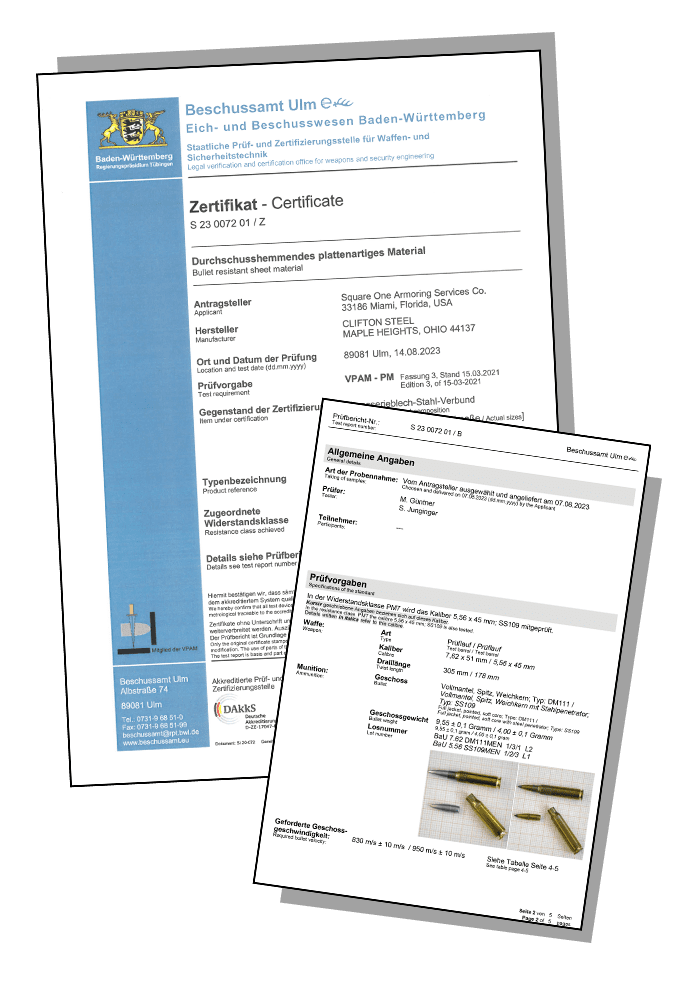

Square One Armoring Services has very strict guidelines in place. All opaque and transparent armor materials have independent ballistic certifications, including Beschussamt Ulm and Mil-Spec documentation. As an additional level of quality control, Square One periodically tests batch samples from the opaque and transparent armor inventory.

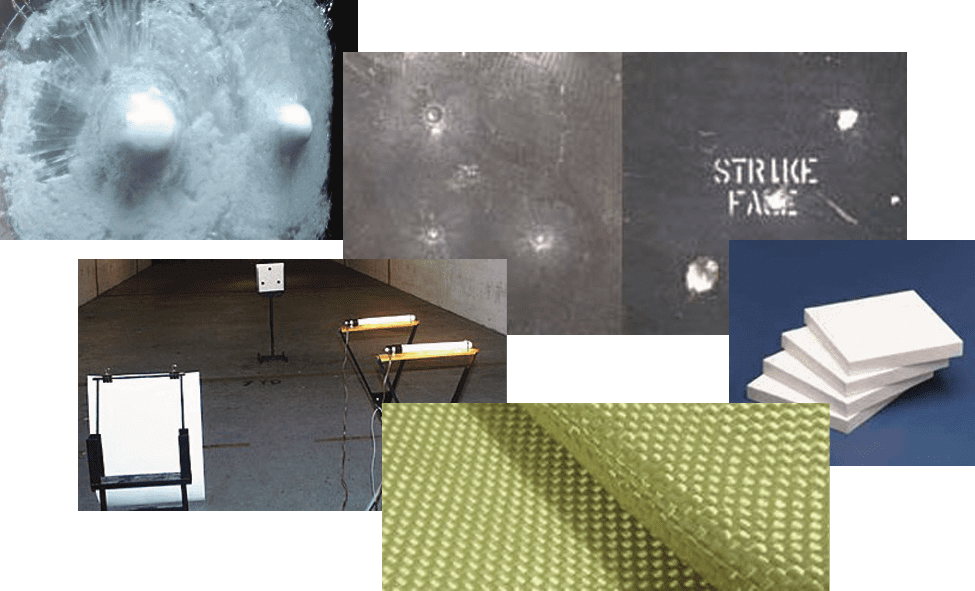

In addition to using existing and well-proven materials, we are constantly testing new materials in search of continuously improving our armor systems. All internal ballistic tests are conducted in a controlled and secure environment.

Complete System Validation

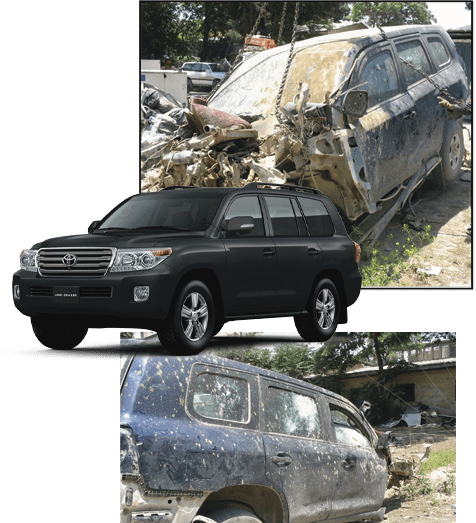

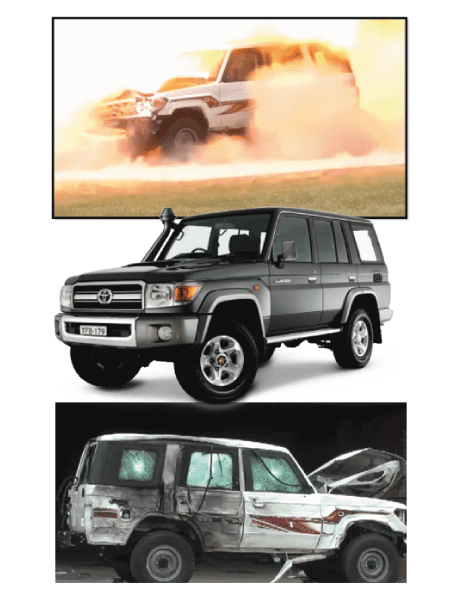

Square One Armoring understands the critical nature of proper armor integration, such as proper welding and fastening techniques, and how each material reacts to different manufacturing techniques. Initial Prototype Platforms are tested past their limits in order to properly address any deficiencies or weak areas and ensure that they perform to the desired specifications.

Real World Survivability